My iTracer

my iTracer

Mein iTRacer ist ein Tool für Röhrenkennlinienmessungen, ähnlich wie der berühmte uTracer. Aber im Unterschied zu diesem kann mein iTracer auch (Steuer-)Gitterströme messen, sogar die kleinen Anlaufströme. Das ist möglich mit einem logarithmischen Verstärker, der von unter 5nA bis 100mA Ströme messen kann.

My iTracer is a Tool to measure tubes like the famous uTracer. But in difference, my iTracer is able to measure grid current, even the small initial velocity grid current. This is due to a logarithm amplifier, which copes currents below 5nA up to 100mA.

Neben dem Steuergitter-Kanal sind da zwei weitere Kanäle. Beide können bis zu 500V Spannungspulse bei 180mA liefern Während einer umschaltbar ist für doppelter Strom / halbe Spannung, kann der andere invertiert werden für grössere negative Spannungen.

Beside the grid channel, there are two futher channels, both capable to deliver voltage pulses up to 500V with 180mA. While one of them is switchable for doubled current/half voltage, the other is invertable for larger negative voltages.

Auf diese Art ist mein iTracer recht flexibel einsetzbar für ein weites Spektrum an Vakuum Dioden, Trioden und Tretoden/Pentoden.This way, my iTracer is quite flexible for a wide range of vacuum diodes, triodes and tretrodes/pentodes.

Als ein nettes zusätzliches Feature, benötigt mein iTracer keine gefährlichen Spannungen - lediglich 60V sowie hohe Spannungen, die trotzdem ungefährlich sind wegen ihrer begrenzen Pulsdauer oder wegen ihrer begrenzten Stromstärke.

As a nice additional feature, my iTracer doesn't need any danger voltage at all - just 60V and high voltages which are safe because of limited pulse duration or limited current.

Es ist ein tolles Tool um hochwertige Röhrenmessungen vorzunehmen, welche eine gute Ausgangsbasis sind für die Erstellung von hochwertigen Röhren Spice Modellen.

It is a good tool to gain high quality tube measurements, which are a good basis for the creation of high quality tube spice models!

The whole iTracer is totally new developed by me from cratch. A key element is the Feedback diode of the log amp, which needs to be hold on constant temperature because of its temperature dependent transfer characteristic.

So, I spent an NTC and a heater next to the feedback diode, and I did my best to thermally couple those parts as good as possible, while the enviroment shall be of as low influence as possible. The solution as showed in the pictures above worked very good - a small spike of 0.18°C is the maximum detectable when blowed by mouth as strong as I can! 🙂

My iTracer got an enhancement to measure tubes in typical thermal condition

At hifi-forum.de, I got the hint that tubes show different curves depending on their plate losses. It was proposed to enhance my iTracer with the posibility to bias the tube with a typical working point during the time between the measurement pulses.

Though actually a simple challenge, it took several month to build this enhancement due to heavily limited freetime.

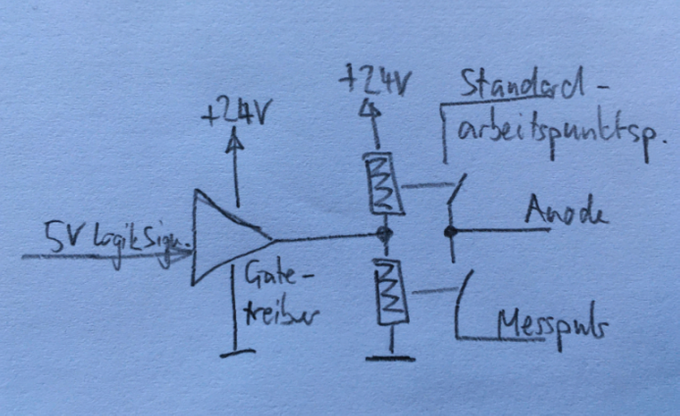

The solution was made with the last free pin of my adruino nano board to control relays switching the tube between the typical working point and the measurement pulses. 24V driven reed relais were choosen, as the local 5V supply of my iTRacer was allready fully loaded:

This simple approach need to be tested whether the "break before make" rule might be violated. The reed relais' datasheet claimed for a break delay time of 0.1ms while the make delay time was stated with 1ms, so theoretically it should work. In practise, the deadtime was much shorter, 88us rather than 0.9ms. But it worked! 🙂

And this is how the enhanced iTracer setup looks like:

The first tube I measured under hot plate conditions was the 6S4A (version with 3 ripps in the anode sheet). This construction shows a reduced gm of about -4% when the anode is hot, compared to the same tube with a cold anode.

The curve differences between hot and cold anode are very construction dependent, as it was a goal of the involved tube development engineers to reduce this effect sufficiently - which was sometime quite succesful, but sometimes not! 😉

Diese Seite teilen